Simulation Modelling

Effective, innovative and powerful

Simulation Modelling

Innovation Industries simulation team comprises of process engineers and developers that can help you map out existing processes, show bottlenecks as well as provide the metrics on the benefits of different options to improve a system.

Our simulations use modern tools can incorporate show known and unknown dynamic variability which helps provide the most realistic estimation of what outputs can be expected, when modifying or validating an existing system.

AnyLogic as well as other tools can be used for full supply chain modelling including Mine, Rail and Port processes and tracks material movement all the way through the system which enables you to quickly identify where bottlenecks will occur and quantify the values that are required to alleviate them.

Previous Work

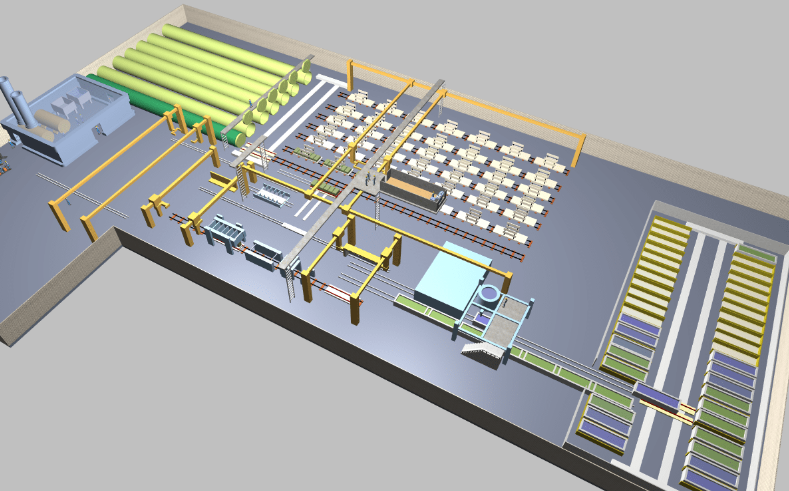

RSM workshop upgrades

We developed a simulation model to show the current maintenance loads on the existing workshop facilities /infrastructure and then the impact of additional new assets. The simulation was a real-time simulation of a 10-year period showing the effects of a new fleet coming into operation at certain times in the future and what this did to maintenance debt. We were then able to look at what workshop layouts and schedules would best handle the new assets and any critical bottlenecks the client should be aware of.

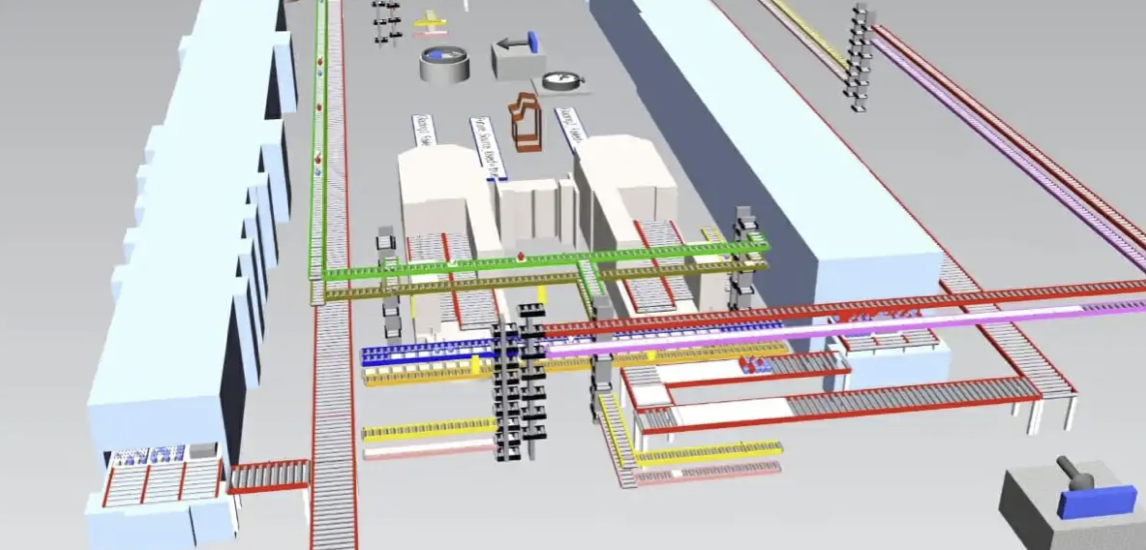

Rail Capacity Upgrades

Building out the client’s rail lines into an AnyLogic model to show current rail tonnes movement through to the Ports. The aim of this project was to understand what additional rolling stock fleet would need to be purchased to achieve the desired increase in throughput. The model was also able to identify future bottlenecks that need to be addressed as cocommitments.

Loading facility and train loop

This project was a basic rail capacity to understand the correct number of FELs, Road Trains and Train rakes to get the desired throughput from the mine site to Port. Using AnyLogic we were able to show the dynamic relationships between the FELs, Car dumper, the stockpile and the road trains. With some natural variation and some expected operational downtimes, the model was able to show how quickly the system can react to unexpected outages/failures or delays.

Supply chain system replacement Project

Advanced Planning System (APS) software package used by the client to manage their supply chain from Pit stocks, through to mine stocks to rail, port and shipping was not providing adequate value. We were part of the team that rebuilt this entire system from the ground up and integrated all their live data as well as planning data to the new tool. This was a 12 month project and is still successfully being used today as a critical business system.

Tailored Simulation Modeling

Innovation Industries uses knowledge and skill to provide simulations and processes tailored to you. Our efficient development helps understand and forecast performance. We identify techniques to help guide your business. These services include:

- Discrete event simulation model development including software packages such as AnyLogic and ExtendSim and SimPy development

- Process mapping

- Schedule development and forecasting logic to feed simulations

- Feed-in from historical data to test model validity

- Supply chain and logistics system optimisation